I am about to replace the 20-year-old hoses. They are starting to permeate, and some even have checking in the outer surface layer...

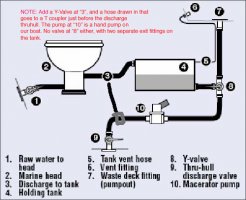

Our '88 model has the then-standard Ericson "full Monty" waste management system that allows direct overboard via Y-valve, or, into a 15 gallon (Ronco Plastics model B-175) holding tank, and then the additional choice of shoreside pumpout via deck fitting OR pumping overboard thru the head discharge thruhull valve.

I find that, unlike some of the diagrams in the catalogs, our holding tank has two (2) 1 1/2" threaded exits at the bottom. One for the deck pumpout and one going back forward to the head compartment to the Whale manual pumpout there.

Anyone else here find this double-exit strategy in their holding tank?

Next question: Why ... or why not?

Most of the folks that I have spoken with echo the advice in some catalog illustrations to just have a Tee fitting in the holding tank exit hose, with the hose off of the Tee going up to the deck pumpout fitting.

Thanks for any comments and advice.

Loren

Our '88 model has the then-standard Ericson "full Monty" waste management system that allows direct overboard via Y-valve, or, into a 15 gallon (Ronco Plastics model B-175) holding tank, and then the additional choice of shoreside pumpout via deck fitting OR pumping overboard thru the head discharge thruhull valve.

I find that, unlike some of the diagrams in the catalogs, our holding tank has two (2) 1 1/2" threaded exits at the bottom. One for the deck pumpout and one going back forward to the head compartment to the Whale manual pumpout there.

Anyone else here find this double-exit strategy in their holding tank?

Next question: Why ... or why not?

Most of the folks that I have spoken with echo the advice in some catalog illustrations to just have a Tee fitting in the holding tank exit hose, with the hose off of the Tee going up to the deck pumpout fitting.

Thanks for any comments and advice.

Loren

Last edited: