Hello All,

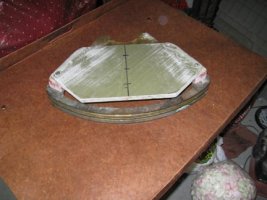

I completed the reinforcement plate to allow the installation of a belowdeck autopilot ram on the steering quadrant of my E38. The reinforcement plate is made of G10 or fiberglass laminate material that is 1/2" thick with additional spacers of the same material but 1" thick. The spacers are required to clear the quadrant stop assembly. This G10 material is extremely tough. I beat on a leftover bit with a large ball pein hammer, hard enough that I would have bent it were it metal, and there was no visible damage.

The plate will be attached to the bottom of the quadrant with (6) 1/4-20 stainless bolts and also glued with 5200 on the mating surface.

Does anyone see any issues with this setup?

Thanks in advance! RT

I completed the reinforcement plate to allow the installation of a belowdeck autopilot ram on the steering quadrant of my E38. The reinforcement plate is made of G10 or fiberglass laminate material that is 1/2" thick with additional spacers of the same material but 1" thick. The spacers are required to clear the quadrant stop assembly. This G10 material is extremely tough. I beat on a leftover bit with a large ball pein hammer, hard enough that I would have bent it were it metal, and there was no visible damage.

The plate will be attached to the bottom of the quadrant with (6) 1/4-20 stainless bolts and also glued with 5200 on the mating surface.

Does anyone see any issues with this setup?

Thanks in advance! RT