sgwright67

Member III

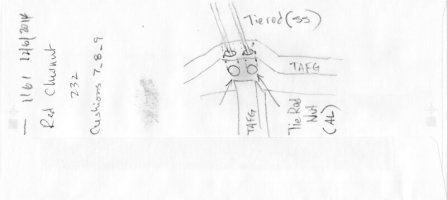

As I consider various Ericson models, I have been trying to categorize them to help me distinguish the various design features, and also to recognize them at the dock. One thing I am unclear on is which boats go the TAFG. Here is my rough list so far. I've left out anything below 27 and above 38. Maybe this info is already on here somewhere?

27, 29, 31I, 32-2, 35-2, 36C, 37: first generation true Ericson designs (as opposed to those inherited from others) with encapsulated longish fin keel

28, 30-1, 30-2: not really sure where these fit?

28+, 30+, 32-3, 34, 34T, 35-3, 38, 381: first with bolt on keels (triangular), not sure about TAFG on these

33RH, 36RH, 34-2, 32-200, 38-200: TAFG and newer interiors but 32 & 38 based on same hull as 32-3 and 381 versions (which implies that the 32-3 and 381 both have the TAFG)

I'd love to know more about the evolution of the designs, and the sailing and structural characteristics of each family of designs.

27, 29, 31I, 32-2, 35-2, 36C, 37: first generation true Ericson designs (as opposed to those inherited from others) with encapsulated longish fin keel

28, 30-1, 30-2: not really sure where these fit?

28+, 30+, 32-3, 34, 34T, 35-3, 38, 381: first with bolt on keels (triangular), not sure about TAFG on these

33RH, 36RH, 34-2, 32-200, 38-200: TAFG and newer interiors but 32 & 38 based on same hull as 32-3 and 381 versions (which implies that the 32-3 and 381 both have the TAFG)

I'd love to know more about the evolution of the designs, and the sailing and structural characteristics of each family of designs.