Loren is right, there is a hefty tooling cost to be borne by the buyer for a new Ronco tank design. Ronco promptly responded by e-mail that they were not the best supplier for this tank. I phoned them and the reason is that it would be cost prohibitive compared to fabricating out of the same material. For a tank this size, and presumably due to its complexity, Ronco said perhaps $2,000 just for the steel mold. Alas, no magic. They did say that the tooling cost could be spread if I could get others to place orders for the same tank. Side note: They have no sales people. So all word of mouth (or Web searches) for business referrals. Anyway, fast feedback is appreciated. Their good prices are due to repeat business for existing molds in their catalog.

So, I'm going to call that welder and see when we can get together to assess the current tank for repairs. I've already lined up several sources and estimates for 16 and 18 gauge stainless steel sheet to use for a repair.

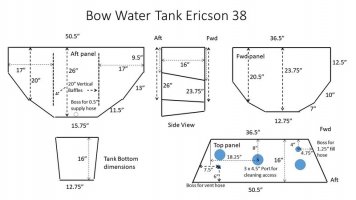

Christian, thanks for making a jpg out of that PDF. I was too tired to do so when it didn't automatically show as a link instead of a blank picture. I'll add the baffles with their measurements and repost a new jpg later.

Appreciate all the feedback!

So, I'm going to call that welder and see when we can get together to assess the current tank for repairs. I've already lined up several sources and estimates for 16 and 18 gauge stainless steel sheet to use for a repair.

Christian, thanks for making a jpg out of that PDF. I was too tired to do so when it didn't automatically show as a link instead of a blank picture. I'll add the baffles with their measurements and repost a new jpg later.

Appreciate all the feedback!