My E38 has a 60 gallon stainless steel water tank in the bow, under the v-berth. I took it out in 2005 while checking for the source of fresh water pooling in the bow. I removed the tank, inspected it, cleaned it and filled it with water and it didn't leak. It went back in and has been in service since then. The past three years have been tough on the water system because we haven't used the boat since the fall of 2015 due to engine problems and other projects, not to mention the non-boating stuff you have to deal with.

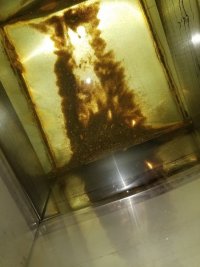

In our limited use of the water system this spring I noticed some brown color sometimes in the water from the taps. So about a week ago I opened up the berth and took that first picture through the inspection port. Most of that sediment is probably rust and some of it sticks to a magnet. There is a very ugly spot on that weld on the left that makes me think there is some internal breakdown going on. The tank has been at least a third full also, for three years, just water sitting in there.

Second picture is to show that you can get it out of there. I had to straddle the opening in order to lift it out of the hole. I might add handles, or fittings on top where I can attach ropes, for lifting purposes. The tank is awkward, obviously, but not that heavy. It goes out of the companionway easily and doesn't threaten my dodger, which is a little lower than many of them out there.

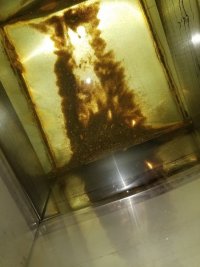

The last picture is some telltale streaks from the welds. The 2005 inspection had identical streaks in a couple spots but they didn't leak. So I'm not sure what I'll find. I'm going to tap all the welds with a sharp instrument and clean the suspicious spots with a wire wheel. I am also thinking about adding two more inspection ports to the top so I can clean the outer areas that are blocked by the vertical baffles. I do want to look at that ugly weld and look for more along the side welds on the inside.

I am hoping to re-install the tank and use it provided it is not just worn out. At least for this season so I can plan a proper replacement over the winter. I'm also thinking about a piece of Dri-Deck under the tank to reduce the moisture trapped between the sloped bottom of the tank and the plywood floor.

In our limited use of the water system this spring I noticed some brown color sometimes in the water from the taps. So about a week ago I opened up the berth and took that first picture through the inspection port. Most of that sediment is probably rust and some of it sticks to a magnet. There is a very ugly spot on that weld on the left that makes me think there is some internal breakdown going on. The tank has been at least a third full also, for three years, just water sitting in there.

Second picture is to show that you can get it out of there. I had to straddle the opening in order to lift it out of the hole. I might add handles, or fittings on top where I can attach ropes, for lifting purposes. The tank is awkward, obviously, but not that heavy. It goes out of the companionway easily and doesn't threaten my dodger, which is a little lower than many of them out there.

The last picture is some telltale streaks from the welds. The 2005 inspection had identical streaks in a couple spots but they didn't leak. So I'm not sure what I'll find. I'm going to tap all the welds with a sharp instrument and clean the suspicious spots with a wire wheel. I am also thinking about adding two more inspection ports to the top so I can clean the outer areas that are blocked by the vertical baffles. I do want to look at that ugly weld and look for more along the side welds on the inside.

I am hoping to re-install the tank and use it provided it is not just worn out. At least for this season so I can plan a proper replacement over the winter. I'm also thinking about a piece of Dri-Deck under the tank to reduce the moisture trapped between the sloped bottom of the tank and the plywood floor.