markvone

Sustaining Member

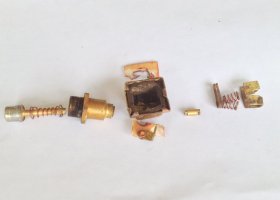

Universal 5424 Diesel High Pressure Fuel Line Disconnect Question

Hi,

I need to disconnect one high pressure fuel line, between the mechanical pump and the injector, to replace a glow plug (the glow plug on the right, see the pictures). I'm planning on removing the tie clamp between that fuel line and the middle line, so that the line to be disconnected is free from the other two. Then loosening the lower fitting on the line at the pump (cover with rag/expect pressure release) and swinging it out of the way.

Do I need to slightly loosen the end of the line at the injector to slightly rotate the line?

Any special re-assembly/bleeding tips?

I've never disassembled a fitting like this and I'm looking for any tips and cautions.

Thanks,

Mark

Hi,

I need to disconnect one high pressure fuel line, between the mechanical pump and the injector, to replace a glow plug (the glow plug on the right, see the pictures). I'm planning on removing the tie clamp between that fuel line and the middle line, so that the line to be disconnected is free from the other two. Then loosening the lower fitting on the line at the pump (cover with rag/expect pressure release) and swinging it out of the way.

Do I need to slightly loosen the end of the line at the injector to slightly rotate the line?

Any special re-assembly/bleeding tips?

I've never disassembled a fitting like this and I'm looking for any tips and cautions.

Thanks,

Mark

Attachments

Last edited: