Its hard to tell how much back-pressure is normal in the system as the boat is new to me.

The thru-hull goes to the strainer, (groco, clean) and then to the pump with 5/8 hard walled hose. The strainer is mounted at about the same height as the pump. If I take the output line off the pump, there is NO water coming out when it isn't working. If I do the vaseline trick, the water comes out the pump fine, I reconnected the output hose, and the system works fine for hours after that. To me that indicates the problem is the pump itself. I will try pushing water backwards through the HX I think, how to get water pressure on the mooring will be my next adventure.

Not sure what causes it to stop working. It didn't work at launch time. It didn't work after sailing on a slight heel to port (5-10deg) twice now, but that could be coincidence. The boat was on the hard for 3 years or so before I bought her. The HX is the newer 3 inch replacement and I put a new zinc in (5424 came with a 2 inch HX originally)

Even new, the pump doesn't have a high flow rate right? Mounted a few inches above waterline it shouldn't be pulling too hard, and the manual says the pump can lift 15 feet!! of water. I've tried a few new impellers, rubber and the Globe run-dry (which don't seem to work as well)

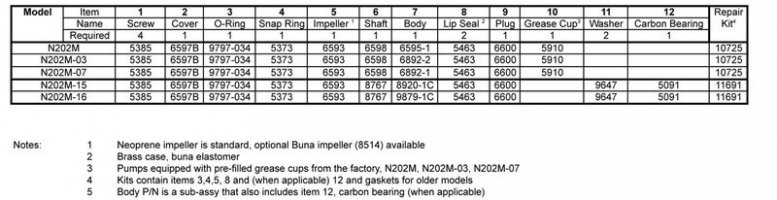

Looking into a new pump, I think I need a N202M-07, as mine has the female-slot shaft. It *seems* like I could get the -15 model though, with the male key shaft, and remove the 4 to 2 hole adapter plate? Does that make sense to anyone? Seems the -15 has a grease-cup-free carbon shaft bearing which is nice.