HerbertFriedman

Member III

I have a small leak in one of my Lewmar portlites and have removed it to reseal it. I am very reluctant to remove the two small screws, separate the frame and remove the glass and gasket, I fear I will not be able to get humpty dumpty back together again. Much to my surprise, I was able to remove both the inside and outside gaskets, I had thought the gasket was like a single channel not two parts. Looking at the tight corner section, is is clear that the gasket was not the seal but rather a thin layer of probably Dow Corning 795 that glued the gasket in place, was the seal, and obviously it failed in lots of places.

I know the Catalina folks sell a refurb kit (!$100) with new gasket, Dow 795 and 3M4000 sealants but again, I fear taking the frame apart. I have ordered some black Dow 795 and my plan is to do away with the gasket entirely and just fill the entire space with 795 using one of those neat "tools" and masking tape to get a nice finished bevel. After looking at the deep channel where the 795 would go, I probably can fill a lot of that space with something to take up uncritical volume and still have at least 1/4 inch of glass for a sealing surface. In that way, if I ever have to remove the 795, there would not be so much to remove.

Also, I have read that once a silicone sealing is used, the surface is "poisoned" so that no other sealant will adhere, hence my idea of using the 795 in place of the 3M4000, I will still use the 4000 to seal the frame to the cabin side. Maybe this is not true for non porous surfaces, I would rather use 4000 rather than silicone, I question the adhesive properties of silicone, sure it is a great gasket material, but I think 4000 is a better adhesive.

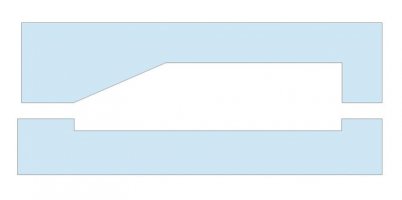

Just as insurance, I looked at getting a new Lewmar portlite of the same tapered shape as a backup. I did find what looks like the same shape from Lewmar but only in a opening version, does anyone know if a fixed version is available. This portlite is really strange, the rectangular portion is not "straight" but rather tapers from about 7 1/2 inches to 7 inches, I guess for aesthetic reasons. Plus there are 4 versions of this window, two for the starboard and two for the port sides, so it is not possible to purchase one backup portlite for all the positions, bummer.

Would like to hear what the mavens out there think.

I know the Catalina folks sell a refurb kit (!$100) with new gasket, Dow 795 and 3M4000 sealants but again, I fear taking the frame apart. I have ordered some black Dow 795 and my plan is to do away with the gasket entirely and just fill the entire space with 795 using one of those neat "tools" and masking tape to get a nice finished bevel. After looking at the deep channel where the 795 would go, I probably can fill a lot of that space with something to take up uncritical volume and still have at least 1/4 inch of glass for a sealing surface. In that way, if I ever have to remove the 795, there would not be so much to remove.

Also, I have read that once a silicone sealing is used, the surface is "poisoned" so that no other sealant will adhere, hence my idea of using the 795 in place of the 3M4000, I will still use the 4000 to seal the frame to the cabin side. Maybe this is not true for non porous surfaces, I would rather use 4000 rather than silicone, I question the adhesive properties of silicone, sure it is a great gasket material, but I think 4000 is a better adhesive.

Just as insurance, I looked at getting a new Lewmar portlite of the same tapered shape as a backup. I did find what looks like the same shape from Lewmar but only in a opening version, does anyone know if a fixed version is available. This portlite is really strange, the rectangular portion is not "straight" but rather tapers from about 7 1/2 inches to 7 inches, I guess for aesthetic reasons. Plus there are 4 versions of this window, two for the starboard and two for the port sides, so it is not possible to purchase one backup portlite for all the positions, bummer.

Would like to hear what the mavens out there think.