Rocinante33

Contributing Partner

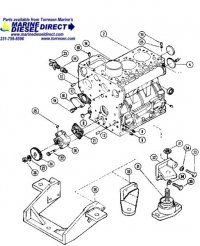

Here is their spec sheet for the recommended mount:

DSATL-M55-16S.pdf

Hmmmm.... PDF file did not load. #!*+# iPad

DSATL-M55-16S.pdf

Hmmmm.... PDF file did not load. #!*+# iPad

Last edited:

I just encountered Maine Sail on changing the motor mounts on an Ericson 34 M25 (while lounging in his redesigned site).

It bears on the general thread topic, and illustrates difficulties he3 calls the "snowball effect".

https://marinehowto.com/replacing-motor-mounts/