Steaming Exhaust isn't about engine block cooling

This reply and mini article is based on fresh water cooled engines:

Generally steaming exhaust on water cooled exhaust systems is not about engine overheating. There are two systems that are interconnected out of convenience, engine cooling and exhaust cooling. (They do share a 1 of the two pumps).

I have seen several engines rebuilt because of steam coming out of the exhaust. In all of these cases, the problem was not solved by the rebuilding of the engine, and in one was not solved by the replacement of the engine entirely with a new one.

Steam is generated in the exhaust by a lack of sufficient water in the exhaust cooling portion of the raw water circuit. The other side of the cooling circuit, the engine cooling side, does not generally have an effect on steam in the exhaust in most situations.

Trouble shooting and thinking it through steps:

#1> If the steam were coming from the engine cooling side on a fresh water cooled engine then the radiator cap would pop and fill the interior of the boat with smelly Propylene Glycol steam and a temperature gauge pegged.

#2> If the steam were coming from the mixing of the cool raw water with the engine cooling water, then the engine cooling water would have to be really hot to heat up the raw water to above 212 degrees (100 Degrees for those of you on the French system). That much heat and steam on the fresh water side would pop the radiator cap, and we would have #1.

#3> If the steam were coming from the cool raw water itself, you would not be able to float in the water without being cooked like a hotdog in foil, so we can discount floating on a sea of steam

(Just put this in here to see if you were reading it!).

#4> Insufficient cooling water going through the heat exchanger, or a significantly undersized heat exchanger would again cause #1

#5> So the only place left for the steam to be generated has to be outside the engine block:

#6 > There is no heat added to the raw water once it leaves the heat exchange at any other place except where the exhaust gases mix in at the mixing elbow (also called the raw water injection point by some mechanics).

#7 > Insufficient water through this point or having the cooling water vaporized could create steam where it mixes with the 500+ degree exhaust gases. (500 degrees.... Hummm That could produce steam easily if it were not cooled enough or fast enough).

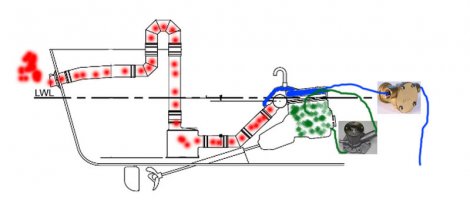

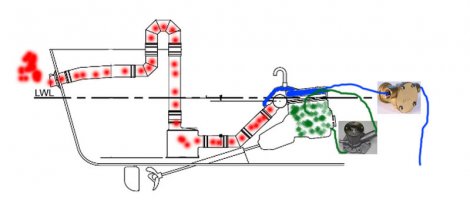

Lets take a look at this crude drawing that is provided by my doppleganger and see if it makes sense. (He isn't very good at photo shop is he?)

So how to fix it?

Take the mixing elbow off, and clean it out, or in most cases replace it.

Also check to make sure that your impeller on the raw water cooling pump is new and that you are not restricting water through the raw water system.:

#1 >Thru Hull (Likely to cause high engine temp)

#2> Strainer (Likely to cause High Engine temp)

#3> Hoses (These can have aneurysms where the internal layer separates and causes a full or partial hose block in some conditions, rare, but not unheard of).(Likely to cause high engine temp)

#4> Heat Exchanger (A frequent issue is broken off impeller bits from previous impeller failure stuck against the raw water tubes. Most times you can get them out with a set of magic fingers). (Likely to cause high engine temp)

#5> Exhaust cooling injection point, or mixing elbow. (Does not cause high engine temp generally).

That should help, and start some conversation that might help.

Guy