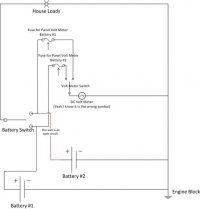

OK, I think the main problem is that you have power applied to the panel when you should not. There should only be power there when you want to use the engine and you turn the switch to do so. If not, what you have is power applied to the lights for the panel and also to the gauges and their associated sending units. This will draw power. From the picture for your panel, it appears that there is a switch for the lights. This should turn off the lights, does it?

I can try at the weekend. You need to identify the wire that comes into the panel that supplies power to it. If you can, remove it and tape it off with electrical tape for now. Then apply power and then see it you are getting voltage at the panel, which you shouldn't.

I've already identified that wire, and inserted a toggle switch as a workaround to disable the power to the panel as the key system doesn't seem to be doing that. When I toggle that switch to off then there's no power to the panel and the problem is solved. But this shouldn't be required if its all working as it should do without my toggle switch workaround

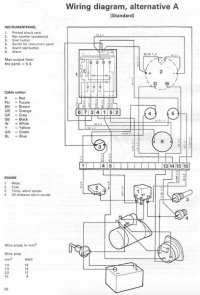

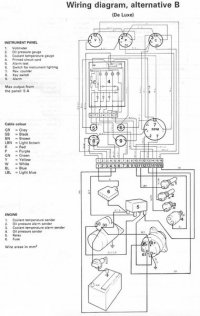

Here is a basic wiring diagram for instruments.

The power for the instrument lights should come from the switch marked "inst light" on your panel which in turn should be supplied from the main switch on your panel when it is on. If it does not get its power from this switch, where does it come from? Does it come from your main panel? The ground in this diagrams is for the lights. Remember, the circuit for the gauges are completed through the sending units for those gauges via the engine ground. With the power removed from the panel, you should be seeing no voltage there, unless there is something connected to it that is feeding voltage. Use the ground for the lights to probe for voltage. Also, if you disconnected the connection at the gauge and got a different ohm reading, why is that since you said you do not have the sending units for these gauges and hence now path to ground. This should be an open circuit then.

See Lorens reply - he'd inserted some text which reinforced that a ground leak can occur when connecting up the new panel to the existing wiring loom, where new sensors are not added. Where is this connecting to give you one reading with it connected and another when it is not? You also said that you were given the panel, does this mean that it is used and not new?

Its a second hand panel but only a few years old

PS The volt meter will get its ground through the same path as the lights as it is just measuring the voltage and there is no sending unit for it.

Maker

Maker