jtsai

Member III

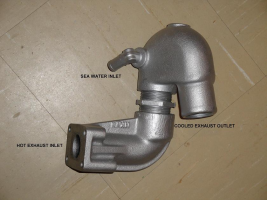

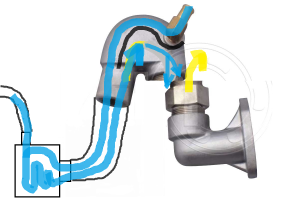

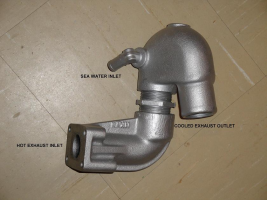

I have been puzzled by the location of the water inlet positions on the various exhaust elbows. Below are three examples of popular configurations. The first one is Beta marine, and the second and third are Universal and Yanmar styles. In the event of an exhaust elbow failure at or near the exhaust flange, won't the water back-flow into the engine block if the water inlet is upstream of the riser injecting water toward the exhaust flange? This is the case except Beta marina exhaust elbow, where the water inlet is downstream of the riser.

This happened to me this summer when the Yanmar style exhaust elbow on the 25XP broke off at thread to the exhaust flange. It was discovered 30 sec. after the engine started but the water was visible in the now exposed exhaust flange. The engine was flushed right away out of caution and found no problems. I was advised I should've closed the raw water seacock and let the engine run for a bit to expel the wet exhaust before shutting down the engine. Right, like I will remember that next time!

But if the water inlet is at the location as shown in the Beta engine, then water should not back-flow into the engine during such event. So why do most marine engines' exhaust elbows have the water inlet at the unfavorable location?

This happened to me this summer when the Yanmar style exhaust elbow on the 25XP broke off at thread to the exhaust flange. It was discovered 30 sec. after the engine started but the water was visible in the now exposed exhaust flange. The engine was flushed right away out of caution and found no problems. I was advised I should've closed the raw water seacock and let the engine run for a bit to expel the wet exhaust before shutting down the engine. Right, like I will remember that next time!

But if the water inlet is at the location as shown in the Beta engine, then water should not back-flow into the engine during such event. So why do most marine engines' exhaust elbows have the water inlet at the unfavorable location?