peaman

Sustaining Member

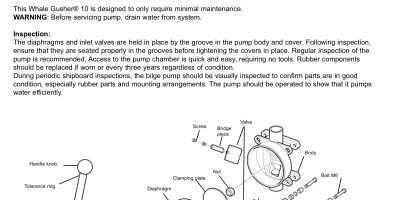

I have two Whale Gusher pumps on my boat, which I believe may be original equipment: one is a bilge pump at the helm, and the other is for head tank overboard pump-out. I recently removed and disassembled the head tank pump and found some corrosion which needs to be addressed.

Except for a bit of internal corrosion, the pump is fairly pristine. It is unfortunate that the corrosion is mostly on surfaces which are critical to the pump operation, and that aluminum corrosion results in expanding growths. I want to restore the pump to service, so I would like to know what might be the best treatment for the corrosion. I have some latex aluminum primer, which was recommended for aluminum exposed to weather. Another choice might be painting with WEST system epoxy or something similar. Since some surfaces must be flat in order to enhance sealing of the flapper valves, any coating must be not too thick.

What are my best choices for treatment?

Also, how often should a pump like this be opened for inspection or service? 35 years seems too long, so maybe 18?

Except for a bit of internal corrosion, the pump is fairly pristine. It is unfortunate that the corrosion is mostly on surfaces which are critical to the pump operation, and that aluminum corrosion results in expanding growths. I want to restore the pump to service, so I would like to know what might be the best treatment for the corrosion. I have some latex aluminum primer, which was recommended for aluminum exposed to weather. Another choice might be painting with WEST system epoxy or something similar. Since some surfaces must be flat in order to enhance sealing of the flapper valves, any coating must be not too thick.

What are my best choices for treatment?

Also, how often should a pump like this be opened for inspection or service? 35 years seems too long, so maybe 18?