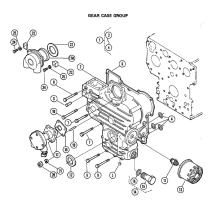

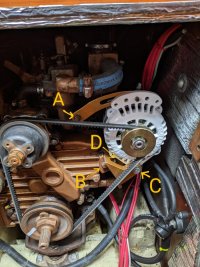

Happy 4th of July ( and Canada Day) weekend to all! The 1984 E35-3 I’m working on needs a new alternator. The engine is a Universal 5432. We tried to remove the alternator, but in so doing the mounting bolts sheared off. The bolt on the slide arm was no problem since the arm itself came off easily. The lower swivel bolt is a different story. It’s frozen in the hole through the alternator. I’m reluctant to hammer it out for fear of breaking the tabs on the mounting bracket. The bracket looks like it’s attached to the engine block with 2 bolts. Is it possible to remove the bracket from the engine? On the parts diagram it looks like there’s a coolant passage underneath it. I don’t want to remove it and have coolant gushing all over the place. Does anyone have experience with this? Any information is greatly appreciated.

Mark

Mark