justin.shay2

New Member

Hi All,

I've been lurking on these forums since I bought my '74 E29 "Condor" in July of '22, but I have to run something by y'all in case I'm doing something crazy.

After removing, rebuilding, and reinstalling my A4, I found my existing exhaust standpipe (riser?) inner pipe is rotted out (see pictures attached.) With several recent improvements to raw water flow, I'm concerned that the inner pipe for the gaseous exhaust is rotted down to the point that the water exhaust will not be forced out to the transom, and instead follow the path of least resistance back to the manifold.

As much as I would love to buy the $775 MMI stainless replacement, it simply isn't in the budget after rebuilding most of the engine. I'm faced with essentially two options - move to a bunch of pipes that elevates the gaseous exhaust above the waterline before being injected with the water & running to a water lift muffler, or try to build my own standpipe muffler. I'm leaning towards building my own standpipe out of steel to save on costs.

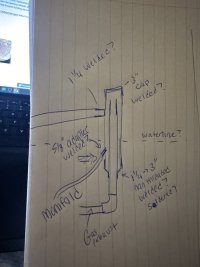

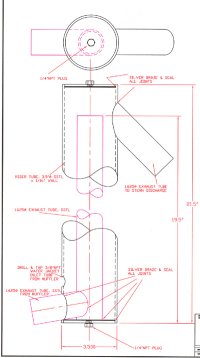

I've attached a diagram I found on OldMarineEngine linked here, and a rough diagram of what I'm thinking on building. It would essentially be a straight pipe of 1 1/4" running straight up, then a 1 1/4" - 3" reducer welded to a 3" pipe that would provide the outer shell for the water to be injected near the base. I'd then weld a cap onto the top of the 3" pipe, leaving a gap for the gas exhaust to provide some pressure to prevent the water from backflowing into the manifold, instead being forced out the 1 1/4" pipe angled down to the transom.

Can anybody tell me if I'm being crazy here? Any tips or concerns?

Thanks all

Justin

I've been lurking on these forums since I bought my '74 E29 "Condor" in July of '22, but I have to run something by y'all in case I'm doing something crazy.

After removing, rebuilding, and reinstalling my A4, I found my existing exhaust standpipe (riser?) inner pipe is rotted out (see pictures attached.) With several recent improvements to raw water flow, I'm concerned that the inner pipe for the gaseous exhaust is rotted down to the point that the water exhaust will not be forced out to the transom, and instead follow the path of least resistance back to the manifold.

As much as I would love to buy the $775 MMI stainless replacement, it simply isn't in the budget after rebuilding most of the engine. I'm faced with essentially two options - move to a bunch of pipes that elevates the gaseous exhaust above the waterline before being injected with the water & running to a water lift muffler, or try to build my own standpipe muffler. I'm leaning towards building my own standpipe out of steel to save on costs.

I've attached a diagram I found on OldMarineEngine linked here, and a rough diagram of what I'm thinking on building. It would essentially be a straight pipe of 1 1/4" running straight up, then a 1 1/4" - 3" reducer welded to a 3" pipe that would provide the outer shell for the water to be injected near the base. I'd then weld a cap onto the top of the 3" pipe, leaving a gap for the gas exhaust to provide some pressure to prevent the water from backflowing into the manifold, instead being forced out the 1 1/4" pipe angled down to the transom.

Can anybody tell me if I'm being crazy here? Any tips or concerns?

Thanks all

Justin